Precision Prototyping

Advanced Manufacturing Solutions for Innovation

Where Speed Meets Microscopic Accuracy

Certifications

ISO 9001 · ISO 13485

Precision Capability

±0.001mm Tolerance

Rapid Iteration

24h Design Turnaround

Trusted by Fortune 500 Companies and Startups Alike:Achieve ±0.003mm Precision through Closed-Loop Process Control.

- Full-spectrum capabilities: CNC Machining, Sheet Metal, 3D Printing, Injection Molding

- Micro-scale to large-format: Features from 0.05mm to 2m dimensions

- Material mastery: 100+ metals, polymers, and composites

- Smart manufacturing: Machine learning-driven process optimization

Active production: Satellite reaction wheels (±0.002mm balance tolerance)

Global projects: 27 countries served in Q2 2024

Quality benchmark: 99.1% first-pass yield rate

Engineering response: <1 hour for critical issues

Certifications: ITAR registered · NADCAP compliant

Prototyping Manufacturer Capabilities

End-to-end solutions from concept validation to pre-series production

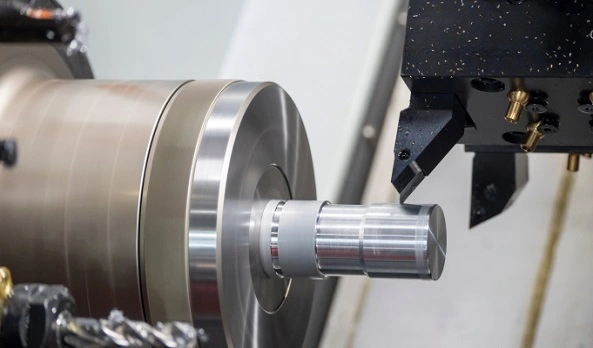

CNC Turning

- ✓ Ø300mm max. diameter

- ✓ ±0.005mm tolerance

- ✓ Aluminum/Stainless Steel

Global Advantage: 100+ Custom Turned Parts, AI-Optimized Pricing10% volume discount

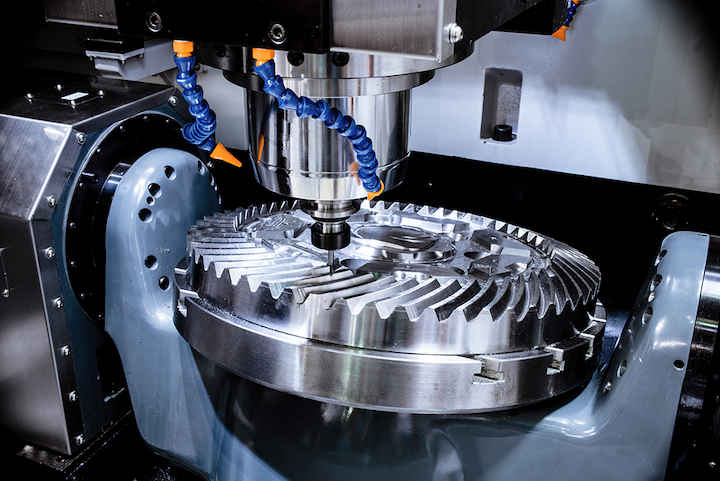

5-Axis CNC Machining

- ✓ 1500×800×600mm work area

- ✓ ±0.002mm positioning accuracy

- ✓ Titanium/Inconel/Stainless Steel

Industry-Leading: AS9100-certified aerospace componentsMedical-grade surface finishes

Micro-Machining

- ✓ 0.05mm micro-drills

- ✓ 50,000 RPM spindles

- ✓ Vision-guided alignment

Applications: Medical micro-fluidics · Watch components

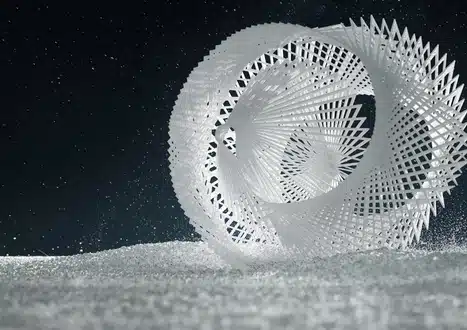

Additive Manufacturing

- ✓ Metal SLM/DMLS

- ✓ Multi-material 3D printing

- ✓ 25μm layer resolution

Certifications: NADCAP AMS7009

Surface Engineering

- ✓ Class 100 cleanroom

- ✓ PVD/Alodine coatings

- ✓ Electropolishing

Compliance: ASTM B117 salt spray testing

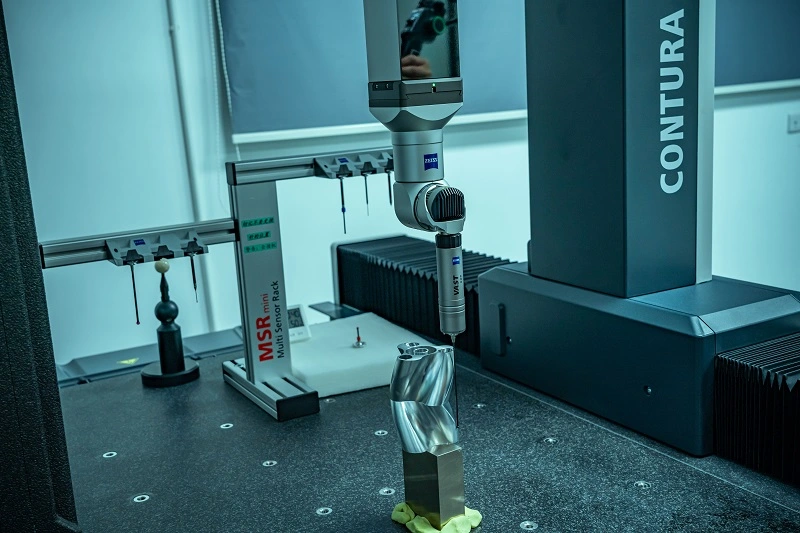

Quality Assurance

- ✓ CT scanning

- ✓ CMM inspection

- ✓ Material certs to AMS

Equipment: Zeiss METROTOM 1500

Tech-Driven Prototyping Workflow for Multi-Material Innovation

From digital concept to physical reality - optimized for metals, polymers, and hybrid systems

Secure Design Submission

- ● AES-256 encrypted file transfer

- ● Auto-DFM analysis for 15+ file formats

- ● Material compatibility checker

Smart Quotation Engine

- ● AI-based cost/time prediction

- ● Virtual twin simulation (FEA/CFD)

- ● Multi-material BOM optimization

Certified Production

- ● Live workshop monitoring

- ● Material batch traceability (AMS#)

- ● Interim inspection reports

Global Compliance Delivery

- ● ITAR-controlled shipments

- ● REACH/ROHS documentation

- ● On-site acceptance testing

Trusted Prototyping Manufacturer for 1500+ Technology Leaders

Michael Tanaka

Advanced Manufacturing Lead

Delivered medical-grade PEEK prototypes with 0.005mm dimensional accuracy, accelerating our product certification process by 8 weeks

Compliance & Certifications

Cross-Industry Expertise:

- Medical PEEK Implant Prototyping

- Aerospace GRP-Carbon Hybrid Structures

Free Multi-Material DFM Guide | 24/7 Engineering Support | ITAR/EAR Compliance Assistance

Specialized Prototyping Solutions for Technology Pioneers

Material-driven innovation across critical sectors

Automotive

- ✓ Custom EV battery enclosures

- ✓ High-precision transmission components

- ✓ Lightweight aluminum designs

Medical Devices

- ✓ ISO 13485 Class 8 cleanroom

- ✓ Biocompatible CoCr/Ti6Al4V

- ✓ Sterilizable PEEK/UHMWPE

Energy Systems

- ✓ IN718/HASTELLOY® machining

- ✓ High-temp ceramic coatings

- ✓ NACE MR0175 compliance

Developing cutting-edge material systems?

Frequently Asked Questions

Next-Gen Prototyping Partnership

● Functional prototypes in 72 hours using 100+ engineering-grade materials

● Hybrid manufacturing with real-time process monitoring (ISO 9001:2015 certified)

● DFM analysis for precision components (tolerance control ±0.005mm)

Consult our engineers for risk-mitigated prototyping solutions.

Technical Consultancy

● Material scientists

● GD&T specialists

● Regulatory compliance experts

● Surface engineering team

Going Rapid

Going Rapid